-

Magnesium Sacrificial Anodes

-

Magnesium Anodes Cathodic Protection

-

High Potential Magnesium Anode

-

Magnesium Ribbon Anode

-

Extruded Magnesium Anodes

-

Prepackaged Magnesium Anode

-

Water Heater Magnesium Anode

-

Wrought Magnesium Alloy

-

Magnesium Alloy Bar

-

High Strength Magnesium Alloy

-

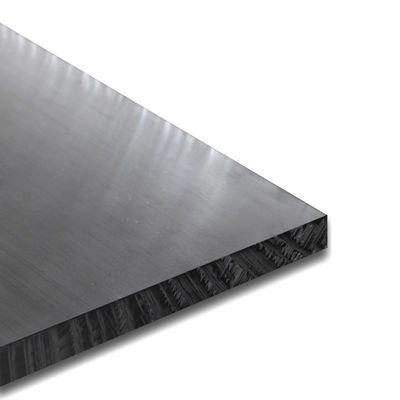

Magnesium Alloy Sheet

-

Dissolvable Magnesium Alloy

-

Magnesium Rare Earth Alloy

-

FedererReliable quality of sacrificial magnesium anode.

FedererReliable quality of sacrificial magnesium anode. -

AliceWell suited to our cathodic protection needs.

AliceWell suited to our cathodic protection needs.

ASTM Sheet Magnesium Lithium Alloy Az91 For Automobile For Roof Panels

| Place of Origin | CHINA |

|---|---|

| Certification | USA: G97,ASTM |

| Minimum Order Quantity | 1000KGS |

| Price | Negotiable |

| Packaging Details | Pallet packing, or on customer's request |

| Delivery Time | 30 Days after receiving the deposit |

| Payment Terms | 50% Deposit , 50% Balance before deliver to the port |

| Supply Ability | 500 mts per month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Keywords | Magnesium Alloy Sheet | Adventage | Ultra High Strength |

|---|---|---|---|

| Service | OEM / OEM | Technical Standard | GB/T 17731-2015 |

| Application | Aerospace Industry | Feature | Heat Treatment Process |

| High Light | ASTM Sheet Magnesium,Sheet Magnesium Az91,Magnesium Lithium Alloy Az91 |

||

High Casting Rate Magnesium Alloy Sheet For Automobile Industry

Introduction:

Compared with cast magnesium alloys, wrought magnesium alloys have greater development potential. Through the control of material structure and the application of heat treatment processes, wrought magnesium alloys can obtain higher strength, better ductility and more diverse mechanics. performance, so as to meet the application requirements of diverse engineering structural parts. Wrought magnesium alloys often need to be heated to a certain temperature and processed by hot forming techniques such as extrusion, rolling and forging.

Features:

- Good thermal conductivity, large expansion coefficient, low elastic modulus, slightly inferior to general aluminum alloys, 300 times that of general engineering materials, and low temperature dependence, can be used to manufacture electronic products requiring good heat dissipation performance;

- It has good damping performance, strong absorption capacity and strong shock absorption, which can be used in situations with severe vibration, and can enhance the safety and comfort of automobiles when used in automobiles;

- Magnesium alloy is a non-magnetic shielding material with good electromagnetic shielding performance and strong anti-electromagnetic wave interference ability, which can be used in communication products such as mobile phones;

Processing performance advantage:

1. The melting cost is only 2/3 of that of aluminum:

2. Excellent die-casting formability: magnesium alloy can be die-casting to manufacture complex parts and ultra-thin shell parts, the thinnest can reach 0.45mm (ABS plastic is 1.2-2mm, aluminum alloy is 1.5-2mm), and the surface quality of magnesium castings and The appearance is obviously better than that of aluminum: the affinity of magnesium die castings and molds is much lower than that of aluminum, and the life of molds is more than 2 times that of aluminum.

3. The production efficiency of die casting is 25% higher than that of aluminum, the metal mold casting is 300-500K higher than that of aluminum, and the lost foam casting is 200% higher than that of aluminum.

4. Good cutting performance: magnesium alloy has low hardness and good cutting performance. The cutting resistance is only 56% of aluminum alloy and 43% of brass. High cutting speed and cheap cutting can be used during processing. Cutting tools, low tool consumption. And without grinding and polishing, you can get a very smooth surface with cutting fluid.

Application:

The automobile industry and the electronics industry have become the industries with the largest demand for magnesium alloys. The use of magnesium alloys in automobiles can reduce the weight by 20% to 25% compared with aluminum alloys. Magnesium alloy extrusions can be used in automotive bearing parts such as seat frames, window frames, chassis frames, wheel hubs, etc. Thin-walled magnesium alloy extruded pipe fittings are used in automobiles, which can significantly reduce weight due to their small cross-sectional area. Magnesium alloy sheets are used to manufacture outer panels of automobile body components (such as doors, covers, guard panels, roof panels, etc.), which can greatly reduce the mass. Magnesium alloys are often used in portable electronic and electrical communication equipment due to their low density and good electromagnetic shielding. In addition to continuing to use die-casting magnesium alloys, it is also a development trend to use wrought magnesium alloys.

Photos:

![]()

FAQ:

Q : Can I add my logo on the boxes/cartons?

A : Yes,OEM and ODM are available from us.

Q : What are the benefits of being a distributor ?

A : Special discount Marketing protection.

Q : How does your factory control the quality of your products?

A : 100% self-inspection before packing. Quality is the life of our factory, first, each raw materials, come to our factory, we will test it first, if qualified, we will process the manufacturing with this raw materials, if not, we will return it to our supplier, and after each manufacturing step, we will test it, and then all the manufacturing process finished, we will do the final test before the commodities left our factory.

Q : Can we mix items in one 20ft container?

A : Yes.

Q : Can I have a visit to your factory before the order?

A : Sure,welcome your visit of factory.

Q : What are the necessary parameters to get the accurate quote?

A : Material chemical composition, anode size, cable and other accessaries information.