-

Magnesium Sacrificial Anodes

-

Magnesium Anodes Cathodic Protection

-

High Potential Magnesium Anode

-

Magnesium Ribbon Anode

-

Extruded Magnesium Anodes

-

Prepackaged Magnesium Anode

-

Water Heater Magnesium Anode

-

Wrought Magnesium Alloy

-

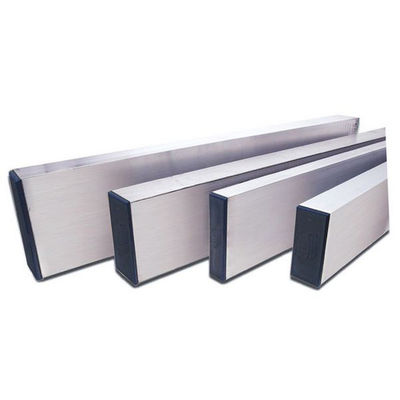

Magnesium Alloy Bar

-

High Strength Magnesium Alloy

-

Magnesium Alloy Sheet

-

Dissolvable Magnesium Alloy

-

Magnesium Rare Earth Alloy

-

FedererReliable quality of sacrificial magnesium anode.

FedererReliable quality of sacrificial magnesium anode. -

AliceWell suited to our cathodic protection needs.

AliceWell suited to our cathodic protection needs.

OEM Wrought Magnesium Alloy AM50 Magnesium Billet In Aerospace

| Place of Origin | CHINA |

|---|---|

| Certification | USA: G97,ASTM |

| Minimum Order Quantity | 1000KGS |

| Price | Negotiable |

| Packaging Details | Pallet packing, or on customer's request |

| Delivery Time | 30 Days after receiving the deposit |

| Payment Terms | 50% Deposit , 50% Balance before deliver to the port |

| Supply Ability | 500 mts per month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Keywords | Wrought Magnesium Alloy | Material | Add Other Elements Based On Magnesium |

|---|---|---|---|

| Feature | Good Conductivity | Service | OEM / OEM |

| Technical Standard | GB/T 17731-2015 | Application | Automobile Industries |

| High Light | OEM Wrought Magnesium Alloy,Wrought Magnesium Alloy AM50,AM50 Magnesium Billet |

||

Good Conductivity Wrought Magnesium Alloy For Automobile Industries

Introduction:

Magnesium alloys have the characteristics of low density, high specific strength and specific stiffness, good dimensional stability, good thermal conductivity and electrical conductivity, vibration absorption and easy processing, so magnesium alloys are one of the competitive automotive wheel quantization materials.

At present, most of the parts made of magnesium alloys in automobiles are die castings. Magnesium alloy die castings are the lightest among all die casting alloys and their service life is longer than that of aluminum alloys.

Magnesium alloy die-casting parts are mainly used for the production of automobile instrument panels, seat frames, transmission housings, steering wheel control system components, engine parts, door frames, wheel hubs, brackets, clutch housings, body brackets, etc.

Features:

Magnesium alloys are alloys based on magnesium and other elements. Its characteristics are: low density (about 1.8g/cm3), high strength, large elastic modulus, good heat dissipation, good shock absorption, larger impact load capacity than aluminum alloy, and good corrosion resistance to organic substances and alkalis. The main alloying elements are aluminum, zinc, manganese, cerium, thorium and a small amount of zirconium or cadmium.

Application:

Wrought magnesium alloys are excellent aerospace materials. For example, the magnesium alloy (AZ31) matrix composite material with silicon carbide whiskers (20% by volume) as the strengthening phase, its elastic modulus is increased by 10%, and the strength is increased to about 450MPa; the United States has used magnesium alloy composite materials to manufacture propellers, For missile tails, etc., naval satellites have used magnesium alloy composite materials for structural parts such as brackets, bushings, and beams, and their comprehensive performance is better than that of aluminum-based composite materials.

Main physical and mechanical properties of commonly used structural materials:

| magnesium casting | Magnesium forgings | Aluminum casting | Aluminum forgings | cast iron | copper | Engineering plastics | |||||

| Alloy model | AZ91 | AM50 | AZ80 | AZ31-H24 | A380 | A356-T6 | 6061-T6 | 5182-H24 | HT350 | Galvanized sheet | ABS |

| Preparation method | die casting | die casting | squeeze | plate | die casting | permanent film | squeeze | plate | sand mold | plate | - |

| Density (g/cm³) | 1.81 | 1.77 | 180 | 1.77 | 2.68 | 2.76 | 2.70 | 2.70 | 7.15 | 7.8 | 1.07 |

| Elastic Modulus (GPa) | 45 | 45 | 45 | 45 | 71 | 72 | 69 | 70 | 100 | 210 | 2.1 |

| Tensile strength (MPa) | 240 | 210 | 380 | 290 | 324 | 262 | 310 | 310 | 293 | 390 | 43 |

| Yield strength (MPa) | 160 | 125 | 275 | 220 | 159 | 186 | 275 | 235 | 320 | 39 | |

| Elongation(%) | 7 | 15 | 7 | 15 | 5 | 12 | 8 | 0 | 26 | 16.5 | |

Photos:

![]()

FAQ:

Q : Can I add my logo on the boxes/cartons?

A : Yes,OEM and ODM are available from us.

Q : What are the benefits of being a distributor ?

A : Special discount Marketing protection.

Q : How does your factory control the quality of your products?

A : 100% self-inspection before packing. Quality is the life of our factory, first, each raw materials, come to our factory, we will test it first, if qualified, we will process the manufacturing with this raw materials, if not, we will return it to our supplier, and after each manufacturing step, we will test it, and then all the manufacturing process finished, we will do the final test before the commodities left our factory.

Q : Can we mix items in one 20ft container?

A : Yes.

Q : Can I have a visit to your factory before the order?

A : Sure,welcome your visit of factory.

Q : What's the necessary parameters to get the accurate quote?

A : Material chemical composition, anode size, cable and other accessaries information.